Independently and objectively

Perform

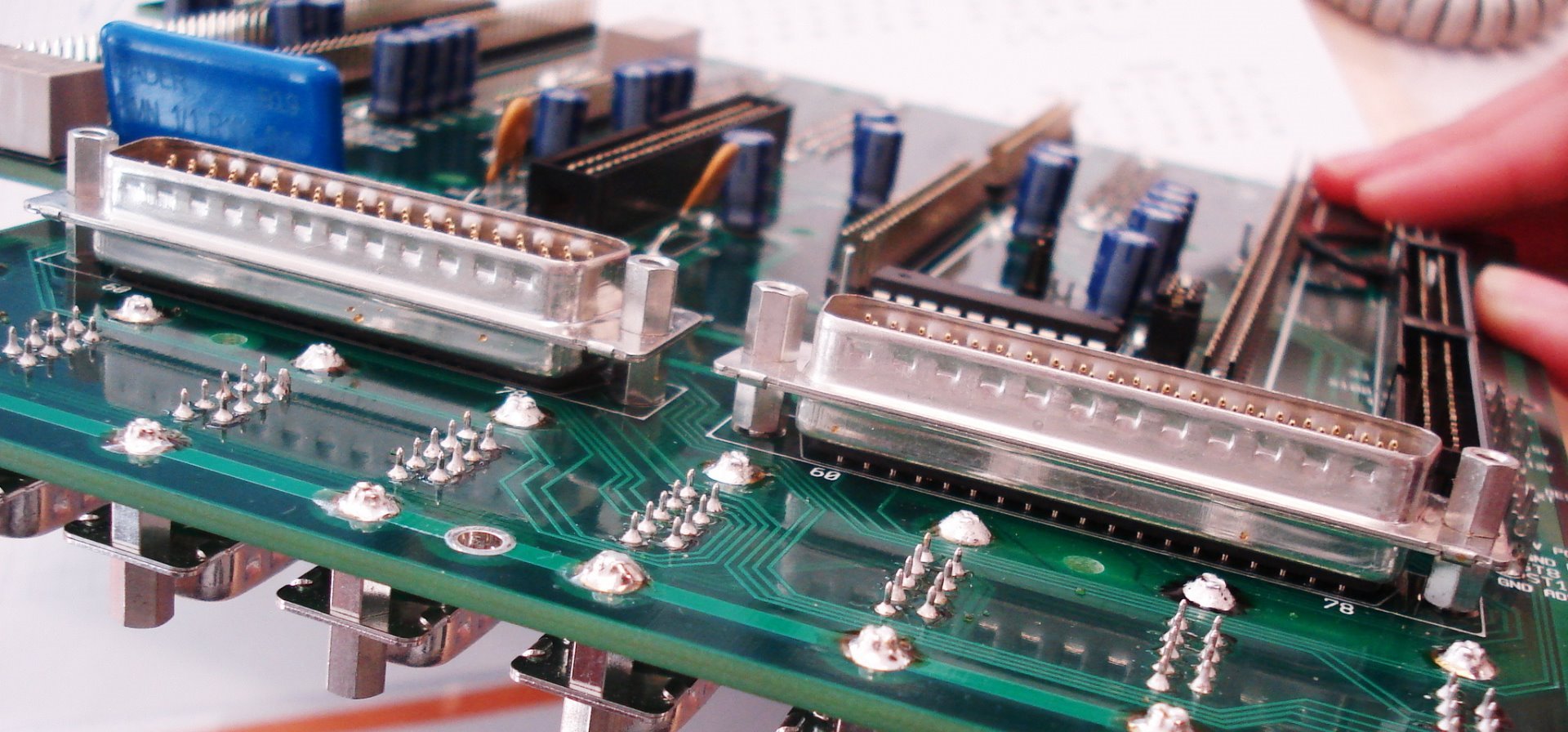

Application support for the SMT and THT assembly

- implementation of new projects and technologies in your production

- selection of production technologies

- selecting auxiliary materials (solder paste, flux, adhesives, chemicals ... etc.) and their application to production

- processing technology procedures and norms

-storage of printed circuit boards (PCB), SMD and THT components

- PCB input optical inspection (detection of visible defects in materials)

- review of PCB design in line with the technical possibilities of the production line

- soldering (depending on the type of alloy and the PCB design)

- PCB washing (compatible consumables)

- - output control (visible faults after soldering)

- qualification of production processes using metallographic sections

Independent arbiter in resolving technology disagreements Analysis of documentation, participation in the production process, design and implementation of the technology solutions. Final protocol with a comprehensive analysis of the project in Czech or English language.

Ground blades metallographic analysis

- Qualification of printed circuit boards (measurement of parameters, hidden defects)

- The qualification process of soldering printed circuit boards, soldering conductors

- Control of the internal structures of electronic components

- Control of layers of materials with thickness measurements

We use metallographic grinder / polisher Buehler, inverted metallographic microscope with a camera and a PC with sophisticated imaging and measuring software.

To achieve the desired output follows the proven principles of the company Buehler and use modern materials of high quality. We hold a certificate for making metallographic sections of the company Buehler. We practice with hundreds of thin sections.

According to documents and our results will produce a protocol to the evaluation and conclusion in Czech or English.